In preparation for our recent trip down to North Carolina on the Nightowl, I install a new rear tire. Naturally, that same tire picked up a nail two days later, which led to some strategizing on how to get home.

The Simple Solution: Plug and Re-inflate

Having traveled cross-country on a motorcycle before (one or twice…), I already had a simple solution a hole in a tire: plug the hole and inflate the tire.

For plugging the hole, I’m a big fan of the Stop-n-Go Pocket Tire Plugger. It includes an ingenious tool for installing a mushroom plug in the hole and it doesn’t take up much space.

For re-inflating the tire, I had an little Kit that contained four (4) CO2 cartridges and a fitting to dump their contents into the tire. I hadn’t needed to use it on the road yet and I didn’t need to use it for this specific plug job since I the hotel I was at had an air compressor on site. (Cue the ominous foreshadowing music…)

With the plug installed and the tire re-inflated, I went about the business of enjoying my trip. We took a nice ride up along the Blue Ridge Parkway that afternoon and didn’t lose any pressure in the repaired rear tire.

Aside: I really like the tire pressure monitoring feature on the Nightowl.

How Long Can You Ride a Plugged Tire?

With our nice ~90 mile day trip behind us, I started thinking about when (and how) to replace the plugged tire. In terms of plugged tire longevity, I’ve found that there are two schools of thought:

- Motorcycle Purist Mentality – A plugged tire is only supposed to get you home. If you’re one the road a long way from home, the plug should get you to the nearest shop that will replace the tire.

- Car Driver Mentality – A properly plugged tire will last a long time. Just ride the damned thing.

The problem with the Car Driver Mentality is that most car tires are not plugged but patched. A plug is a seal that you insert from outside the tire, which is really convenient when you’re on the side of the road in the middle of the nowhere since you don’t have to remove the tire to install the plug. A patch is a seal that you use to cover the hole from the inside of the tire, which requires that the tire be taken off the wheel, patched, and reinstalled. Some of the nicer patches include a plug-like protrusion that you pull through the tire to help keep crap from filling the hole and possibly working its way through to the patch.

While it’s true that a properly patched car tire can last 10s of 1,000s of miles, we’re not talking about patches here. We’re plugging our motorcycle tires and hoping for the best. Consequently, the Motorcycle Purist Mentality is often the best practice: get that tire replaced as soon as possible.

Replacing Tires on the Road

There are two primary challenges to replacing tires while traipsing around the country on a motorcycle:

- Where can I buy a replacement tire that (hopefully) closely matches my current tire?

- Who is going to mount and balance the tire?

For years and years, I didn’t really worry about the either question. I was riding the Cruiser and every Harley dealer on the continent (including several independent shops) had my tires in stock and ready to install.

When I bought the Vector, the first question began to be a concern. Yes, the Vector was still a Harley, so all I had to do was get to a dealer. The V-Rod models, however, use different tires and some dealers are not wildly enthusiastic about keeping them in stock. This could result in a longer trip to get to a dealer that actually had the tire in stock, but the solution still wasn’t too daunting.

Now that I have the Nightowl, both questions can pose real challenges. The stock tires on the Nightowl are Metzeler Roadtec Z8s. These tires are only used on a few heavy touring bikes. None of the Harley bikes use them, so Harley dealers are out. Metric Bike dealers may have them, but they’re not stock on any of the heavy touring bikes from Japan (Goldwings, Concours, FJS, etc.). Consequently, my best bet is a BMW motorcycle dealer, and they’re not all that common.

The second question can also pose a problem. During this specific adventure, I found a dealer in Louisville, KY that sold both Harleys and BMWs. Better yet, they had my tire in stock.

Time to rejoice, right?

The problem was that only Harley techs would be working on the day I would be passing through (Monday) and they were uncomfortable with unmounting/mounting tires on BMW rims because of the tire pressure sensor inside the tire. (Apparently, one HD tech broke a sensor while replacing a BMW tire and had to pay for the part out of his pocket.)

These conditions, along with the need to make the trip from North Carolina back to Michigan in two days, forced me to extend the life of the plugged tire as long as I could.

The Trip Home

After I plugged my tire down in North Carolina, we went for a 90 mile ride along twisty two-lane roads, never exceeding about 60mph (96kph). This caused no problems and gave me a nice (and false) sense of security that I was going to be OK heading for home, even though home was over 600 miles (965km) away.

The first leg of the trip home was through twisty two-lane roads and the tire was fine. It wasn’t until shortly after we got on a less-twisty two-lane US highway that our speeds increased a bit and the plug failed… for the first time (more ominous foreshadowing).

Installing Plug Two

Inspection of the situation revealed that the plug was no longer filling the hole in the tire; it was gone. I didn’t know if the plug got forced out of the hole or fell inside the tire. I just knew that I need to install another.

Lucky for us, we were just over a mile down the road from a Harley dealer and a gas station. Being close to Harley dealer meant that we had no shortage of fellow bikers stopping to help (I think we peaked at five (5) helpful bikers watching my efforts). Being close to the gas station meant that the helpful electrician who stopped to help volunteered to take the tire back up the road to the gas station to fill it.

Note: This would usually raise eyebrows at the prospect of removing the rear wheel just so a guy can drive it up the road, but the Nightowl is a BMW K1600, so removing the rear wheel takes about two (2) minutes.

While our good samaritan was putting air in our re-plugged tire, I consulted RoadTrip (my vehicle data log app) and discovered that I had gone 161 miles (259km) on that patch. I figured that, if I had to, I could install a few more plugs on the way home.

Our samaritan returned. I reinstalled the wheel, packed up our tools, and headed down the road.

Installing Plug Three

The next plug failure came a mere 29 miles (47km) later. This time I could see a gas station about a half-mile (0.8km) away, so I rolled down the hill on the nearly-flat tire and into the gas station, all the while hoping that I wasn’t destroying the tire and ending our trip right there.

The tire seemed to have survived that abuse, so I went about installing another plug. Like before, the last plug was nowhere to be found. It either got spit out or swallowed into the tire; I couldn’t tell which.

With so quick a failure, I really began to think about getting a replacement before we got home. This was a little frustrating since I knew I had two brand new tires (front and rear) waiting in my garage to be installed before my next big trip in two weeks. Still, if we have to install a plug this often, we’ll never get home.

While the gas station we pulled into was closed (it was Sunday), there was still power to their air pump. This was good since it provided inflation without us having to use up our CO2 cartridges (more foreshadowing). With plug number three installed, we headed down the road again, albeit at a lower rate or speed. We hoped that the lower speed would make the plug last longer.

We stopped for lunch another 40 miles (64km) up the road and I made a few phone calls to figure out where we could get a replacement rear tire installed. The nearest BMW dealer was the aforementioned establishment up in Louisville, KY, a mere 200+ miles (322km) away. They wouldn’t want to work on it until Tuesday, so they were out. There were a bunch of metric bike dealers in Lexington, KY, but none of them were open on Sunday so they weren’t available to tell me that they had the required tire in stock. Our options were getting a bit thin.

Since we had gotten further than 29 miles (47km) on this plug running at slower speeds, we decided to push on at our snail’s pace in hopes that the plug would continue to hold.

Installing Plug Four

With our tire problems, we decided that riding a longer route home through the twisty (and fun) roads of eastern Kentucky wasn’t a good idea. We needed a direct route, which meant we needed to take I75, even if it meant hunkering down in the right lane and going 60mph (96kph).

It was only a few miles along I75 that plug three gave up. Karma threw us a bone and made the failure happen on an uphill stretch with an extra lane for slow trucks, which gave us a little more room to make our repairs.

As usual, the plug had disappeared. Assuming that they were blowing out, I added a little rubber cement (purchased during the lunch stop) to the plug, in hopes that it would make it stay in the hole.

Note: Stop-n-Go does not require that you add rubber cement when installing their mushroom style plugs. They do say that it is an optional step.

With plug number four installed, it was time to re-inflate the tire. I got out my nifty little CO2 inflation kit and proceeded to add the contents of all four of cartridges into the rear tire. When I checked the resulting tire pressure, I saw only 20psi, not the required 42psi.

“Confutatus maledictis flammis acribus addictis!” When a biker utters curses in Latin, keep your distance.

While I carefully considered our limited options (really, I was just fuming), Karen discovered that there was an open gas station a mere four miles (6.4km) up the highway. I wasn’t thrilled with the prospect of riding that far on a half-filled tire, but almost all of our other options involved flatbed tow trucks.

Aside: The tire pressure sensors on my travel trailer tires report both tire pressure and temperature. I would have really liked that feature on this juncture of the trip. The temperature reading on the rear tire would have helped me tell if the extra stress from running the tire so under inflated was destroying the tire.

We made the gas station without the rear tire eating itself and topped it off with the required air pressure. Since most of the miles since the last plug failure were fairly tame, we surmised that the speed was still too fast to allow the plugs to last. We elected to push on at 55mph (89kph).

Stretching the Last Plug

As it turned out, we were able to make plug number four last all the way back to Michigan. I attribute this success to the following:

- We limited our speed to 55mph (89kph).

- We purchased an electric air pump to give us a better option than the crappy CO2 inflation kit (a bit like putting on rain gear to keep the drops from falling).

I strongly suspect that our odds of success were helped by the temperatures dropping significantly as we drove late into the evening on Sunday.

For our last 200 miles (322 miles) on Monday, we elected to take all back roads from Vandalia, OH to home. This was, ostensibly, to keep our speeds down but it was really to keep my spirits up after being passed by every vehicle on the highway the day before (Oh, the shame of it…).

What Makes Plugs Fail?

Once a plug is installed and holding air, the optimistic thought is that it should last a while. Well, maybe… and maybe not.

Note: There are a bunch of reasons that plugs don’t seal; I’m not going to cover that here.)

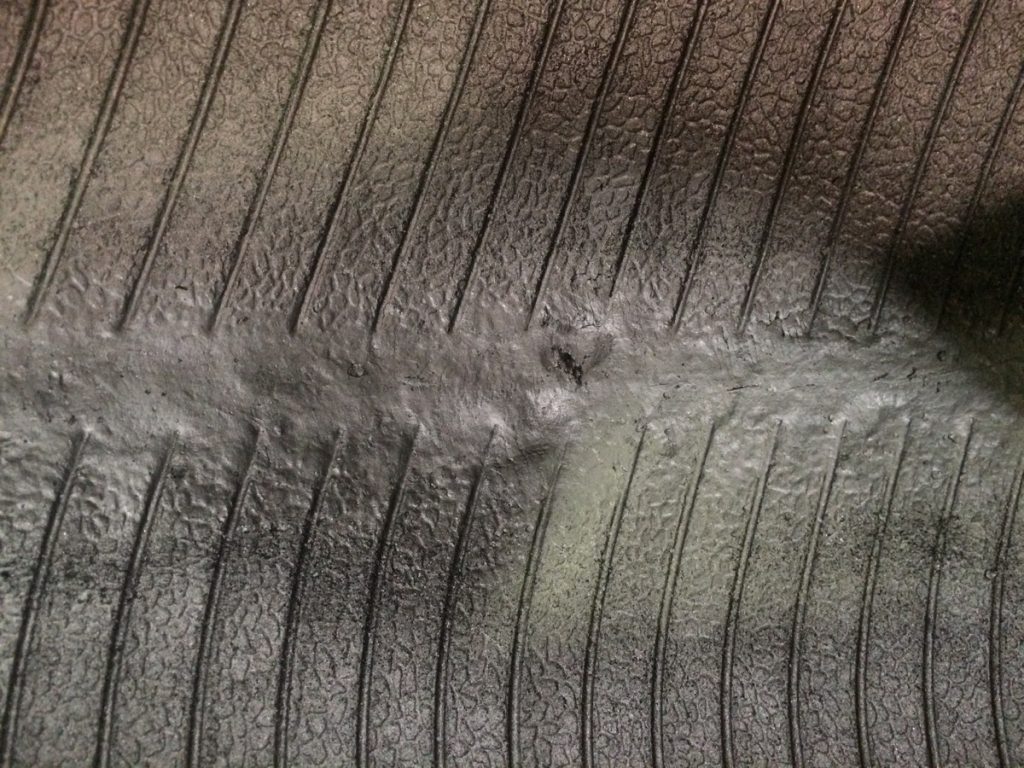

Upon replacement of the rear tire, I discovered that the plugs had not been getting spit out of the rear tire. Inside the injured tire I found all four mushroom heads of the plugs that had been installed.

As you can see, none of the installed plugs were intact. Each one had been cut into two pieces, one falling into the tire and the other falling away. Most likely, this was due to the steel belts in the tire eating their way through the soft rubber of the plug as the tire flexed while rolling down the road. Since the hole was only an inch (2.5cm) off the center line of the tire, there was a fair amount of flex each time the tire went from a compressed state from carrying the load to a released state for the rest of its rotation.

With high speeds came higher temperatures, which further softened the plugs and made them an easier meal for the steel belts. If the failure had been further to the outside of the tread, I suspect that the flex would have been less and the plugs would have lasted longer.

That same flexing probably contributes to the plug making its way into the tire. This, naturally, is accelerated by the cutting of the plug. In the case of the last plug, the mushroom cap was sliced off by the steel belts and the remainder of the tire was still making it’s way into the tire. It just happened to last long enough for us to get home.

Lessons Learned

All in all, this trip provided a valuable learning experience. Ok, yeah. I admit, it sorta sucked, but we survived and got home on time anyway, which makes the overall result kinda cool. The following are the adjustments to my standard motorcycle operating procedures for future trips:

Replace the Plugged Tire ASAP

We ran a total of 676 miles (1088km) on our plugged rear tire. Pretty fully loaded. Two up.

Uh-huh (nodding head). That’s a shitload.

In the future, I’m inclined to alter course for the nearest dealer and eat the cost of getting the right tire installed by the right staff. In a pinch, you can replace at an independent shop and install whatever similarly sized and load-rated tire he/she may have available. If you have to install an odd tire, dial back on your riding habits a bit. A bike with mismatched tires will not handle as consistently as it does with matched tires.

Baby the Tire Plugs

As we learned, speed and high temperature kills the plugs. When riding a plugged tire, keep your speed at 55mph (89kph) or below.

Carry a Pump

Those CO2 cartridges that I was hoping to use may be the schizzle for repairing bicycle tires, but they probably wouldn’t even fully inflate one of those razor-thin front tires you see on those over-customized choppers at the big bike meets. There’s no substitute for a good electric pump. I bought one of the smaller Slime pumps at a Walmart on the way home, just so I had it. Once I was home, I immediately ordered the righteous solution to my on-board pump needs: a MotoPumps Air Shot.

This unit is small, doesn’t draw much power, and comes with enough adapters to mate it to any bike you might own… or come across by the side of the road.

Don’t Ride a Flat or Under-Inflated Tire Unless You Have To

During the trip home, I had to ride on the tire for two less-than ideal stretches:

- The half-mile (0.8km) ride on a flat tire after plug number two gave up.

- The four mile (6.4km) ride on a half-inflated tire to get to a gas station.

Once I had the tire off, the results of this abuse was readily evident.

The middle of this tire was partially melted and blistered. Not badly, but bad enough that the tire was partially compromised. I suspect that most of the damage was caused by running it for that short stretch while it was flat.

In retrospect, I should have stopped right there, replugged the tire, inflated it with the cartridges, and then topped it off at the gas station. In the future, this won’t be a problem since I have a pump on board. There won’t be any reason to stop immediately and make repairs.

2 thoughts on “Adventures in Tire Plugging”